An overview of calorimetry

This technique measures the temperature and heat of transformation of materials (mainly liquids and solids) as well as their heat capacity.

Calorimetry – Introduction to Calorimetry

Calorimetry is a method whose principle is to measure, as a function of temperature, the heat produced or absorbed during the transformation of a sample of material. During this measurement, the temperature of the sample is precisely controlled.

The device that allows this measurement is simply called a calorimeter. Depending on the principle of their temperature control and their sensor, calorimeters can be called isothermal, adiabatic, isoperibolic or by other exotic terms.

Whatever its name, a calorimeter is mainly composed of:

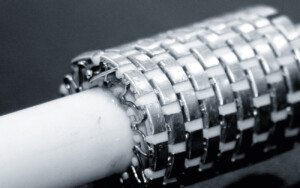

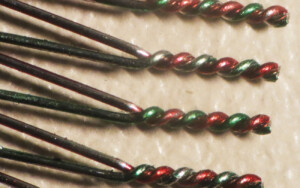

- A sensor to receive one or two cells containing, for the first, the sample to measure, and possibly for the second, the reference material. This sensor integrates a device, most of the time composed of thermocouples, which measures continuously

o Either a heat flow: the heat flow between the sample and its environment. When two cells are used, it is the difference in heat flow between the sample and the reference that is measured. The calorimeter is then called differential.

o Or a temperature: the temperature of the sample, the temperature of the oven or the difference between the two.

- Sample holder cells whose material and design are chosen according to the measurements to be made.

o The material used is usually a metal inert to the sample. Ceramics can be used for very high temperature applications.

o The cells are usually closed by a plug, or even completely sealed and resistant to pressures of several hundred bars, etc.

o They can simply contain a free space to receive the sample, or integrate tools to make mixtures, provide agitation, a gas or liquid flow, etc.

- An oven, often called a calorimetric block, in which the sensor, the sample and its reference are placed during the experiment. This oven is equipped with a temperature control system that allows it to precisely heat, cool or maintain the temperature according to a profile programmed by the user.

The calorimeters cover the needs of research and development of materials in different forms (solids, powders, liquids). They can also be used to control and optimize their production processes. They are used over a wide range of temperatures and applications.

Calorimetry and temperature measurements

When a sample is heated in a calorimeter and undergoes a transformation, its heat flow to the calorimeter block increases and then returns to a base value after the transformation is completed. Thus, the analysis of a curve representing the heat flow as a function of time or temperature allows to characterize this transformation.

This analysis allows, depending on the case, to determine the melting, crystallization, reaction, decomposition and phase change temperatures (solid-solid transformations) of materials.

Temperature measurements by calorimetry are essential to control the behavior of these materials, in particular when they must be subjected to a thermal treatment during their manufacture, their use or their recycling.

Calorimetry and heat measurements

The heat of the measured thermal effect can be determined by a simple mathematical treatment. For this purpose, the calorimeter must be calibrated beforehand using reference materials or special calibration cells.

This mathematical treatment, which can be carried out easily by any user, enables the determination of the heats of fusion, crystallization, mixing, formation, reaction, decomposition and phase change (solid-solid transformations) of materials. Depending on the cells used, the influence of conditions such as pressure, atmosphere, humidity can be studied.

The heat flow difference curve can also be used to distinguish between endothermic effects (which absorb heat: e.g. melts, transitions to a less stable phase) and exothermic effects (which release heat: e.g. crystallizations, most decompositions).

These measurements are for example important to evaluate the proportion of a component or phase in the material, or its purity, and to estimate the heat to be supplied to or removed from the material before using it in an industrial process.

Calorimetry and heat capacity measurement

The heat capacity (Cp) characterizes both the ability of a material to absorb part of the heat it receives (the rest being transferred) and the temperature increase it will undergo by absorbing this heat. It is therefore a key piece of data to understand, design and optimize systems where heat exchange is an important process: engines, heating systems, industrial processes, batteries, furnaces, etc.

Calorimetry, through the use of a simple procedure consisting of a series of measurements, is able to measure the values of Cp at a temperature, or its variation over a temperature interval chosen by the user.