Thermal Analysis and Calorimetry techniques

Whether you are interested in the thermal stability of a material, its reactivity, its composition or heat management, calorimetry or thermal analysis techniques will provide you with useful information to meet your challenges.

Which technique for which measurement ?

There are many calorimetry and thermal analysis techniques that can cover various characterization needs, under experimental conditions (temperature, atmosphere, pressure,…) that simulate the real conditions of use of materials. The following pages provide information on the principle of these techniques, the typical measurements performed, and the main application fields.

-

Differential Thermal Analysis (DTA)

This technique measures the temperatures of transformation of materials. It is particularly used to characterize the phase changes of inorganic materials at very high temperatures. It is often referred to as DTA.

-

Differential Scanning Calorimetry (DSC)

This technique measures the temperature and heat of transformation of materials as well as their thermal capacity. It is usually referred to as DSC.

-

Simultaneous Thermal Analysis (STA)

Simultaneous thermal analysis measures the thermal stability of materials, and provides information about their reactivity or composition. It is sometimes called STA (for simultaneous thermal analysis). It is also often referred to as TG-DSC or TG-ATD as this technique combines thermogravimetry with DTA or DSC methods.

-

Thermogravimetric Analysis (TGA)

Thermogravimetric analysis measures the thermal stability of materials, and provides information on their reactivity or composition. It is sometimes referred to as TGA.

-

Thermomechanical Analysis (TMA)

Thermomechanical analysis measures the variation in dimensions of materials as a function of temperature. It is called TMA (for thermomechanical analysis) or dilatometry.

-

Calorimetry

This technique measures the temperature and heat of transformation of materials (mainly liquids and solids) as well as their heat capacity.

-

Adsorption Analysis

Manometric techniques measure how much a material is capable, under controlled pressure and temperature conditions, of capturing or releasing a particular gas. They are also able to measure the rate at which these phenomena can take place.

-

Evolved Gas Analysis

The coupling between thermogravimetric analysis and gas analysis methods such as MS (mass spectrometry), FTIR (infrared spectrometry) or GC-MS (gas chromatography-mass spectrometry) allows further analysis of the composition of a material or its thermal decomposition process.

-

Humidity

Moisture can affect the performance and stability of many families of materials. Comparing measurements in a dry atmosphere with measurements at controlled humidity levels can help characterize this influence.

-

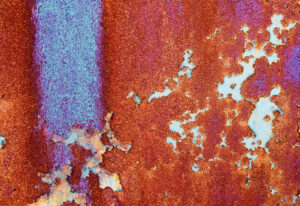

Corrosive

The service life of many materials used in industry or in everyday’s life is limited by their reactivity towards their environment: oxygen, humidity, salinity, acidity are factors that can accelerate their reaction.

-

Pressure

Applying high gas pressure can affect the performance and stability of many families of materials. Comparing measurements at atmospheric pressure and under various gas pressures helps to characterize this influence.

-

Magnetic saturation

The magnetic phases of hard metals give them specific properties. Specific saturation measurement – also know as Sigmametry – is ideal for checking the composition of metal alloys in which one phase is magnetic. It is particularly applicable to materials for cutting tools used in machining, hard steels for mining, and for cement or aggregate grinding processes. It is also ideal for examining materials used in the manufacture of magnets or soft magnetic composites.