Characterizing materials by measurements under corrosive conditions

The service life of many materials used in industry or in everyday’s life is limited by their reactivity towards their environment: oxygen, humidity, salinity, acidity are factors that can accelerate their reaction.

Measuring under corrosive conditions

Materials corrosion being a chemical degradation phenomenon, it can be characterized by performing analyses in real corrosive conditions, enabling the monitoring of this chemical reaction’s progress with time.

Corrosion in a gaseous medium can be studied by thermogravimetric analysis, which monitors the evolution of a material sample’s mass over time when it is exposed to a given temperature and to controlled atmosphere conditions.

Corrosion in a liquid medium can also be studied by calorimetry if the degradation reaction at the origin of the corrosion releases high enough heat to be measurable.

In both cases, it is possible to either simply compare the time required to reach a given reaction rate, or to determine the reaction rate and perform further kinetic studies.

It is important to note that regardless of the analyzer used, it must be protected against the effects of the corrosive environment: it is the material sample that must corrode, not the analyzer!

Thus materials corrosion characterization can be performed with analyzers featuring more or less complex furnaces, gas flow systems, crucibles or sample holder cells options. Depending on the chosen medium and the temperature range of the analysis, these options are for example parts made of reputedly inert metals, ceramics, polymers such as Teflon, or silica glass.

Applications of measurements under corrosive conditions

It is possible to compare analyses of a given material under various corrosive conditions in order to determine its limits of use. It is also possible, for given corrosive conditions, to compare various compositions or structures of materials in order to select the most resistant to these fixed conditions.

Many materials are exposed to more or less demanding corrosive conditions that require studies and analyses. We can mention for example metals, ceramics and/or polymers used :

- in certain industrial processes: reactors for the chemical industry, waste incinerators, etc.

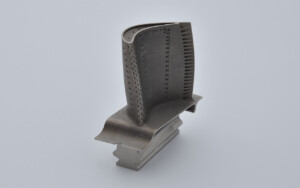

- in energy production systems: nuclear reactors, turbines, thermal power plants, etc

- in systems for transport, aeronautics or defense: thermal engines, turbojet engines, boosters, etc