Calorimetry and gas sorption analysis for catalysts and adsorbents

Calorimetry and gas sorption analysis, alone or combined, can be used to characterize the surface properties of catalysts and adsorbents. This is essential for improving process performance or selecting the most suitable materials for energy and environmental processes.

Characterize sorption, desorption, selectivity data, coke content

If you need to select the best catalyst for an application, or to define the applications of a new adsorbent, we have solutions to help!

They can handle gas-solid, vapor-solid, or liquid-solid interactions.

-

Sorption isotherms

TGA and Manometry characterize how much gas or vapor a material can capture. With these methods, you can measure and compare sorption isotherms.

-

Sorption kinetics

If a solid substrate adsorbs a lot of gas but the sorption takes too long, it isn’t applicable. With TGA and manometry, you can measure how fast the sorption takes place between the gas and the solid.

-

Selectivity

If you’re interested in separation processes, the best materials adsorb more of the desired gas, faster. You can compare sorption isotherms and kinetics to characterize selectivity against various gases.

-

Heat of sorption

To select the best catalysts, you need to understand their surface chemistry. You can measure heat of sorption by coupling calorimetry with manometry. A large amount of heat means a strong interaction between the catalyst surface and the test molecule, and vice versa.

-

Coke content

You can ensure your catalysts work for longer with TGA. A typical application of TGA is the quantification of the coke deposits on a catalyst’s surface during its operation.

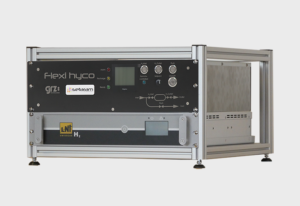

Associated products